Empower production and QA teams with full-lifecycle visibility.

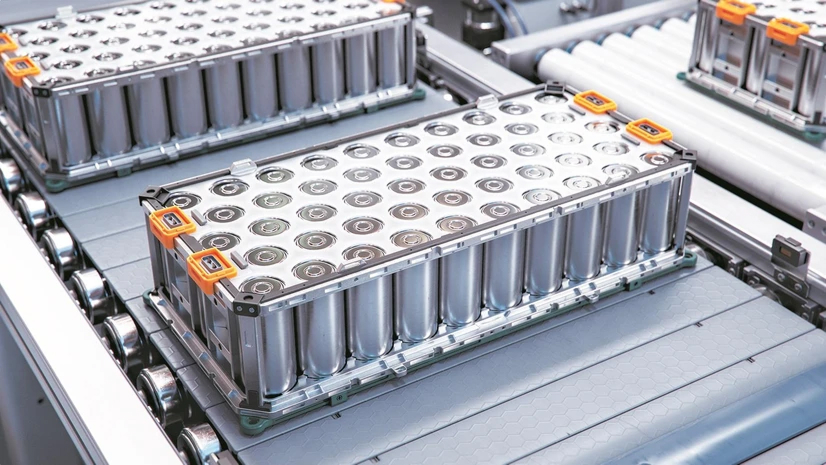

Our platform gives gigafactories real-time insights, actionable workflows, and acceleration certification so quality teams catch issues early and operations keep every module traceable.

- Create tamper-proof passports at formation with chemistry-level metadata.

- Trace cathode, anode, and electrolyte lots across mixing, coating, and stacking.

- Detect weld, pick-and-place, and bonding anomalies within minutes.

.jpg)